Optimizing Mix Design: Part 2

PUMPABILITY PAYS: THE DOLLARS AND SENSE OF MIX DESIGN OPTIMIZATION

by Jon S. Belkowitz, PhD, PE; Mallory A. Westbrook; Daniel M. McCoy, PE

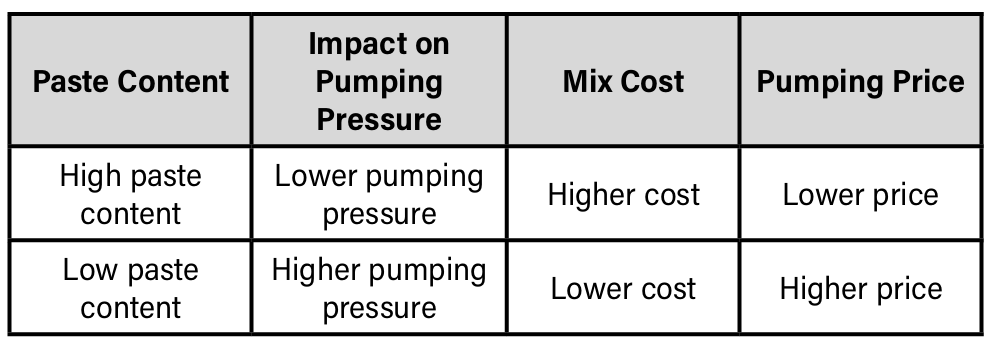

In this article, we explore the technical and financial impacts of optimizing concrete mix design for pumpability in construction projects. We offer key insights, such as the importance of achieving an optimal aggregate gradation to minimize pump pressure, balancing paste volume within a well-graded granular skeleton, and managing risks like segregation and excessive concrete pump pressures. Proper mix design not only reduces issues like line clogging, but also ensures smoother operations, better efficiency and cost savings. By understanding and leveraging these strategies, concrete pumping professionals can achieve regulatory compliance, reduce project costs and enhance the durability of their work, solidifying their competitive edge in the industry. The graphic below offers a quick overview of paste content relative to pumping pressure and cost.

THE IMPORTANCE OF MIX DESIGN

Concrete pumping is a crucial element in construction, but its success heavily depends on one thing — an optimized concrete mix design. Without it, projects can face inefficiencies, higher costs, and even equipment failures.

Proper mix design is more than just selecting the right cement and aggregates; it’s about achieving the perfect balance between the granular skeleton and paste volume. This balance directly impacts pumpability, reducing line pressure and minimizing risks like segregation or blockages that can disrupt operations.

By fine-tuning mix designs, concrete pumping professionals unlock a range of benefits. These include smoother workflows, significant cost savings in production and pumping, reduced carbon footprint and enhanced project efficiency. This article dives into the technical and financial advantages of mix optimization, offering insights to help you stay ahead in the competitive world of construction.

KEY COMPONENTS OF CONCRETE MIX DESIGN FOR CONCRETE PUMPING

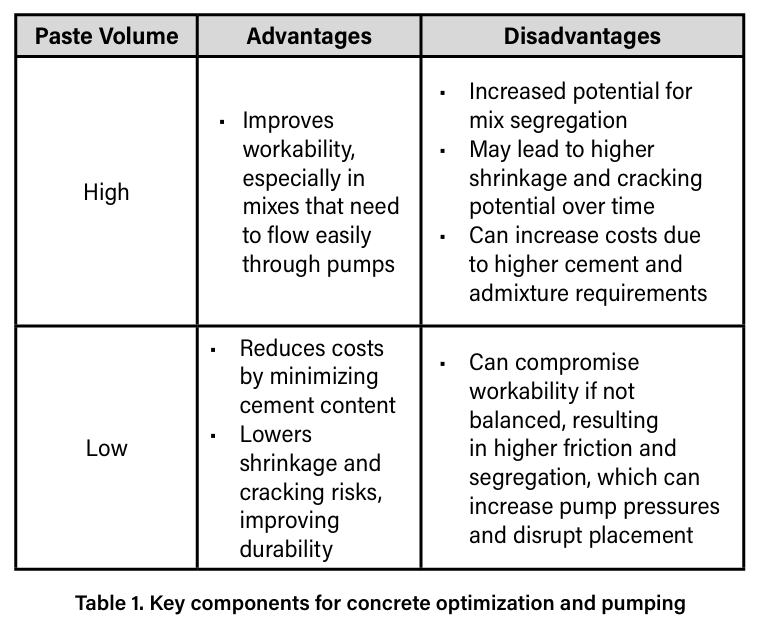

When it comes to optimizing concrete mix design, paste volume and granular skeleton play a critical role in determining the overall performance, pumpability and workability of the mix. Paste volume refers to the portion of a concrete mix comprised of cementitious materials, water and supplementary components such as admixtures. This paste envelops the aggregates and acts as the binding phase that ensures cohesion, workability and strength in the final mix. A well-calculated paste volume ensures that the aggregates are adequately coated while maintaining sufficient lubrication for smooth pumping and placement operations.

By fine-tuning the paste volume in harmony with a well-graded granular skeleton, concrete producers can create the environment for consistent pumpability and lower line pressures, all while staying cost efficient and meeting equipment durability targets.

Excessive paste within a concrete mix can act as a lubricant, leading in extreme cases to instability and inconsistent pump pressures. This can result in difficulties during placement and may compromise the overall uniformity of the mix. On the other hand, an insufficient amount of paste can generate a harsh mix, which increases the energy required for pumping. This issue often manifests as higher line pressures or, in extreme cases, blockages within the pumping system. To achieve optimal results, contractors must carefully fine-tune the paste volume in conjunction with a well-graded granular skeleton. This balance allows for consistent pumpability, reduces line pressures, and ensures a high-quality surface finish. At the same time, it promotes cost efficiency and meets durability objectives, aligning with both economic and performance goals on construction projects.

GRANULAR SKELETON AND AGGREGATE GRADING

The granular skeleton is the backbone of any concrete mix design, functioning as the structural framework that determines both the mechanical performance and pumpability of the mix. It consists of fine and coarse aggregates, which are carefully graded and packed to reduce void spaces and ensure the optimal balance between workability, strength and durability. This skeleton works in conjunction with the paste to create a cohesive and robust mixture that can be efficiently placed and finished.

The aggregate properties — size, shape and grading — play a critical role in defining the performance characteristics of the concrete mix. Well-graded aggregates, meaning a combination of various particle sizes, ensure that the void spaces between larger aggregates are filled with progressively smaller particles. This not only minimizes the porosity of the granular skeleton but also reduces the demand for excess paste to fill voids. Angular aggregates tend to increase interlock and mechanical stability, whereas rounded aggregates provide improved workability and require less water and cement for lubrication. The targeted selection of these properties enables mix designers to optimize both the structural integrity and operational efficiency of the concrete.

Proper grading directly reduces the risk of segregation, which is detrimental to both pumpability and consistency in placement. When aggregates are uniformly distributed throughout the mix, the heavier coarse aggregates are less likely to settle, and the finer materials remain evenly dispersed. This consistent composition is crucial for reducing differential movement within the mix, ensuring smooth pumping through the pipeline, and achieving a uniform surface finish. By optimizing the grading curve, mix designers can achieve a dense, homogenous granular skeleton that resists the forces of segregation during transportation and placement.

The porosity index of the granular skeleton is a critical parameter that quantifies the volume of voids within the combined fine and coarse aggregates. When aggregates are properly graded, the porosity index decreases significantly due to the efficient packing of particles. For example, adding smaller-sized aggregates to fill the interstitial spaces between larger aggregates results in a denser skeleton with fewer voids. This reduction in porosity translates to a lower demand for paste, as less cement and water are required to fill the remaining spaces. A low porosity index not only enhances the mechanical properties of the hardened concrete, but also contributes to cost-efficient mix designs by reducing paste volume.

The interplay between granular skeleton optimization and paste volume management underpins the advancement of high-performance concrete. By leveraging these principles, professionals in construction can ensure consistent mix performance, cost effectiveness and compliance with regulatory standards — all while minimizing risks during pumping and placement.

IMPACT OF PASTE CONTENT ON CONCRETE PUMPING

The paste portion of a concrete mix primarily functions to bond aggregates and provide workability; however, an excessive amount of paste can introduce several technical challenges that compromise both pumping performance and mix robustness.

An overabundant paste content typically creates a disproportionately thick lubrication layer along the interior walls of the pumping pipeline. While this lubrication layer facilitates smoother material flow and reduces initial pumping friction, it can also lead to increased shear stresses and uneven flow distribution within the pipeline. Under elevated pumping pressures, these conditions significantly raise the likelihood of flow instabilities and line blockages, which can delay construction projects and increase operational costs.

From a structural perspective, excessive paste diminishes the robustness of the mix by heightening the risk of segregation. Without a well-proportioned granular skeleton to stabilize the mixture, heavier coarse aggregates are more likely to settle over time, forcing finer materials and water to migrate upwards. This imbalance results in the formation of a weaker interfacial transition zone (ITZ), where the bond between paste and aggregate becomes compromised. Such a scenario not only undermines the long-term durability of the concrete but also impacts the surface finish quality, presenting aesthetic and structural challenges.

To mitigate these risks, precise control of paste volume must be paired with an optimized granular skeleton design. Ensuring a tightly packed aggregate structure limits the movement of individual particles during pumping and placement, thereby promoting a more homogenous mix. By achieving this balance, professionals can enhance pumpability without sacrificing durability and performance, ultimately supporting cost-effective, compliant and high-quality construction outcomes.

While the paste portion of a concrete mix primarily functions to bond the aggregates and provide workability, an excessive amount of paste can introduce several challenges. First, an overabundance of paste may create a disproportionately thick lubrication layer along the inner walls of the pumping pipeline. While this layer facilitates easier pumping, it can also lead to greater shear stresses and uneven flow rates, increasing the risk of line blockages under high pressures.

Additionally, excessive paste reduces the robustness of the mix by increasing the potential for segregation. Without a well-packed granular skeleton to restrain movement, the heavier coarse aggregates can settle, causing the fine material and water to migrate upwards. This results in a weaker interface zone and may compromise the surface finish quality. Therefore, precise control of paste volume and granular skeleton design is essential to maintain a balance between efficient pumpability and enduring performance.

STEPS TO EVALUATING AND ADJUSTING CURRENT MIX DESIGNS

When evaluating and adjusting current concrete mix designs to optimize performance, durability and cost effectiveness, a systematic approach is essential. Below are the recommended steps for leveraging a method focused on analyzing and comparing material volumes within the mix design:

- Break down the mix into paste and granular skeleton volumes. Start by separating the mix into its two fundamental components - paste volume (cementitious materials, water and any added chemical admixtures) and granular skeleton volume (aggregates, including fine and coarse particles). This breakdown provides a clear understanding of the mix's structure and its influence on workability and performance.

- Evaluate the existing ratios. Calculate the proportion of paste to granular skeleton in the· current mix design. Excess paste content may improve short-term workability, but it can inadvertently increase costs, reduce durability and compromise pumpability consistency. A detailed evaluation of these ratios is critical for identifying areas that require adjustment.

- Assess material properties and interaction. Examine the properties of the aggregates, such as gradation, shape and surface texture, in relation to the paste content. An optimized granular skeleton design ensures tightly packed aggregates, reducing unnecessary paste volumes while still maintaining workability during placement.

- Compare paste volume and granular skeleton for optimization. By comparing the volume of paste to the granular skeleton, identify the potential reduction in paste content without compromising the mix's pumpability and workability. The goal is to achieve a balance where the granular skeleton is designed to provide structural support while the paste adequately coats and binds the particles for effective performance.

- Adjust and test reduced paste content. Gradually adjust the mix to reduce the paste volume while maintaining the granular skeleton's integrity. Perform tests to confirm that the reduced paste content supports workability, pumpability and compliance with strength and durability requirements. Testing ensures the balance between performance and cost reduction is achieved.

- Document and iterate the design. Carefully document the adjusted mix proportions and all test results. Where necessary, iterate the design to further refine the balance of paste and granular skeleton, ensuring the solution aligns with project needs, regulatory standards and long-term performance expectations.

OPTIMIZING MIX DESIGN WITH REDUCED GRANULAR SKELETON VOLUME-TO-PASTE RATIOS

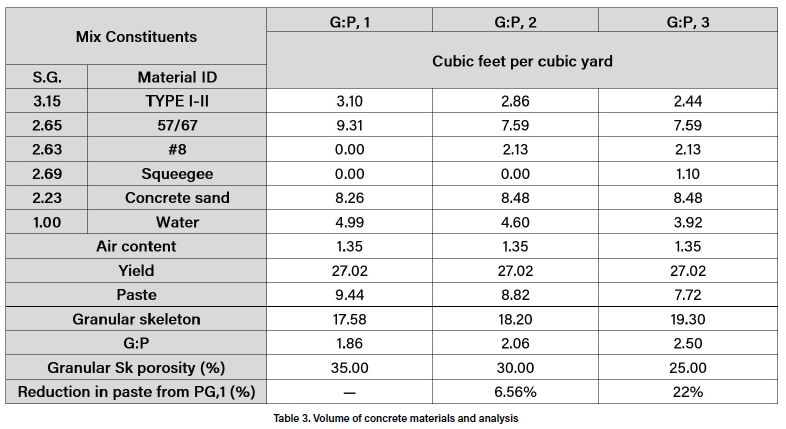

Achieving a balance of granular skeleton volume to paste volume in concrete mix designs is crucial for optimal performance on paper and for pumping concrete in the field. This not only enhances the workability and durability of the mix, but also ensures cost efficiency and adherence to regulatory standards. Below, we explore three mix designs with reduced granular skeleton volume to paste volume ratios, detailing the material volume calculations and highlighting the tools and methods for monitoring pumping pressures and mix performance. The following table presents three distinct mix designs with adjusted ratios, focusing on maintaining consistent performance while optimizing material usage. Each calculation reflects the material volume in cubic feet per cubic yard of concrete. The concrete mix designs outlined in Table 2 demonstrate various adjustments to the material constituents to optimize cost efficiency, durability and performance. Mixes are designed with varying granular skeleton to paste volume ratios (G:P), illustrating the impact of these changes on material proportions on the paste content (excessive and deficient).

The cement content is reduced progressively across the mixes, effectively decreasing paste volume listed in Table 3. This reduction enhances cost efficiency while ensuring durability remains uncompromised. The volume and size of coarse and fine aggregates is increased incrementally from mix 1 to mix 3 to make up for the reduction in paste content. This adjustment improves the granular skeleton’s packing density, which reduces the paste requirements while maintaining optimal structural integrity. Fine aggregates are carefully adjusted to ensure a balance between workability and pumpability, supporting ease of application in various settings. Water content is slightly reduced in alignment with the decreased cement(itious) content. Water-reducing admixtures are utilized to retain the desired slump and workability levels, ensuring the mixes are still practical and manageable during application. Additionally, air entrainment is adjusted across all mixes to ensure appropriate levels of entrained air. This modification guarantees freeze-thaw durability, making these mix designs suitable for a wide range of environmental conditions and construction projects. Ensuring the success of these optimized designs requires real-time monitoring of pumping pressures and mix performance. Advanced tools and resources play a pivotal role in this process: • Pressure sensors for pump monitoring: Install pressure sensors on concrete pumps to continuously monitor pressure levels. High pressures can indicate improper mix consistency or inadequate paste volume.

- Rheometers: Use rheometers to measure the concrete’s flow properties. This ensures that the mix remains within acceptable workability parameters.

- On-site testing equipment: Employ slump and flow tests, unit weight measurements and air content meters on job sites to ensure consistency between designed and delivered mixes.

- Performance analytics software: Leverage software tools that integrate with batching plant systems to track mix proportions, monitor material volumes and analyze batch-to-batch variability.

By combining calculations with advanced monitoring tools, construction professionals can ensure that these reduced granular skeleton volume-to-paste volume mixes meet performance benchmarks. This approach minimizes project costs while enhancing the concrete’s durability, making it ideal for projects requiring consistency and compliance with industry standards.

SUMMARY AND NEXT STEPS

- Recap of the benefits of optimized concrete mix design. Opti-mized concrete mix design plays a crucial role in achieving durability, cost eff iciency and compliance with regulatory standards. By tailoring the proportions of mix constituents, construction professionals can enhance material performance, reduce waste and ensure consistent quality across projects, ultimately extending the lifespan of built structures and minimizing long-term maintenance costs.

- Key recommendations for industry professionals to refine practices. To refine their practices, industry professionals should prioritize selecting the right cement(itious) types, aggregates and water-to-cement ratios based on specific project requirements. Regularly reviewing and updating mix designs through performance-based testing helps ensure that they meet both project demands and changing regulatory standards. Leveraging reliable technical data and consulting with trusted suppliers can further streamline the process and enhance decision-making accuracy.

- Encouragement to adopt innovative approaches for better results. Adopting innovative approaches, such as advanced admixture technologies and new testing methodologies, allows professionals to maintain an edge in the competitive construction industry. By integrating these advancements into workflows, professionals can achieve greater efficiency, reduce proj-ect timelines and address sustainability goals effectively. Ultimately, staying open to innovation is key to driving better results and ensuring continued success in construction projects.