SNAP COUPLINGS: DON’T PULL THE PIN!

(unless you’re prepared)

Concrete pumping is a critical process in construction, and the reliability of the equipment used can significantly impact the efficiency and safety of the operation.

When concrete pumping started to gain wider usage in the late 1960s, pumpers were using lower-pressure metric couplings with wedges. These designs are still used in developing markets without regulation. Con Forms was one of the founding members of the ACPA in 1974 due to the frequency and severity of injury in the early days of concrete pumping.

One essential component in this system is the snap coupling. While two-bolt couplings should be used whenever possible due to their more secure locking method, snap couplings are useful in portions of the laydown system that may need to be moved or detached frequently.

However, snap couplings have one of the highest rates of employee injury in our industry. This is not something to be taken lightly. Sorry to be so blunt, but there is no reason to dance around this issue — poor quality, damaged and worn-out couplings can kill. Handles fly open with force that can break bones if you don’t — PIN IT! Safety glasses are not optional, as any residual pressure could spit concrete or aggregate into the eyes.

Today, pumps are operated much closer to their maximum pressures due to more demanding job requirements and harsher mixes that require higher pressures to pump. Forged couplings offer increased strength and ductility over similar cast designs. Ductility is the measure of a metal’s ability to stretch without breaking. Forged couplings will stretch and deform at failure, which creates a slow loss of pressure. However, when a cast coupling fails, it can crack and result in a violent eruption that endangers anyone working near the system. In some cases, the gasket can extrude to allow a slower loss of pressure, but this is not a certainty and not all coupling designs have this fail-safe.

RISKS OF WORN-OUT CLAMPS

While many of these safety considerations must be kept in mind by operators on the job site, there is a vital safety policy that must come from the leadership at any pumping contractor: Proactive removal of worn components should be stressed as an important and approved practice.

The longer a clamp, pipe or hose is in service, the greater the cumulative wear and damage that occurs. This damage compounds if excessive force is needed to install the clamp, leading to greater — and unnecessary — risks. It’s crucial to remove worn-out components from service and replace them with new ones at the first sign of problems. Cheap insurance! The cost of a new clamp is minimal compared to the potential costs of failure in use. Failure of just one clamp can translate to severe injury to any personnel nearby, costly litigation, damage to nearby objects, large losses of concrete and downtime on the job site for everyone depending on the pump delivery.

The operational philosophy of “run to failure” must be addressed and discouraged by the highest levels of your organization.

SAFE USE OF SNAP CLAMPS

Snap clamps are ideal for system locations where speed changes are needed or where the clamps are frequently opened and closed. However, even when installed properly, snap clamps have a higher chance of opening than their bolted counterparts. External forces acting upon the handle, such as snags or blows from moving objects, can create accidental disengagement. Several safety considerations must be addressed when using snap couplings.

COUPLING CHOICE AND SYSTEM DESIGN

- Snap couplings are not as strong as two-bolt couplings. Use bolted couplings whenever possible.

- Snap couplings must be regularly inspected, maintained and adjusted properly.

- External mechanical loading will reduce working pressure. Proper use of supporting brackets can reduce bucking and pulsing stresses on your coupled connections.

- Use hose caddies and skid pans. These low-cost accessories provide significant benefits that should be considered for all laydown systems, particularly where snap couplings are in place. Both items protect your clamps from accidental disengagement and wear due to friction and vibration of an operating system. The skid pan is very helpful on jobs where a coupling that is connected to pipe or hose is moved over rebar reinforcement. It provides improved safety and efficiency for your team manning that portion of the pumping system.

VISUAL INSPECTION

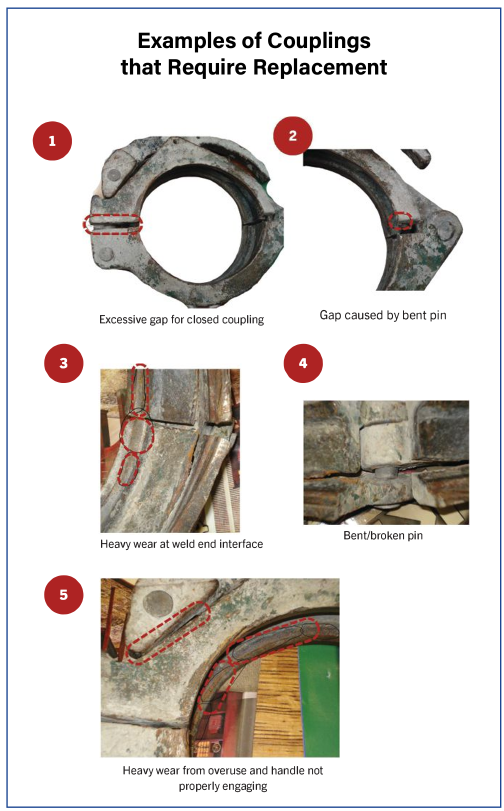

Each coupling should be inspected prior to installation. If any of the following conditions are found, the coupling should be removed from service.

- Excessive wear on the body of the coupling — cracks or dents are visible in the body of the coupling or the embossed pressure rating is too worn to be read

- Repeated usage and opening/closing can damage or bend the coupling, requiring great force to close and putting a large strain on the handle. If the coupling shows bent, broken or distorted links or pins in the handle, it should not be used. A damaged coupling reduces the safe operational pressures of the system.

- If the safety pin cannot be properly inserted due to alignment or damage to the handle.

- Excessive wear affecting the contact surfaces of the coupling with the lip of the pipe’s weld end. This can increase local stresses on portions of the coupling.

- For adjustable snap couplings, damaged threads or concrete build-up that prevents the coupling from closing properly

INSTALLATION AND OPERATION

- Ensure gaskets are free of concrete residue and properly lubricated, and that the coupling cavity is clean with no residual concrete that may impede its engagement with the weld end.

- Examine the coupling and gasket for cracks or tears that may prevent a proper seal.

- ALWAYS WEAR EYE PROTECTION. Eye injuries are among the most common injuries on job sites and can have serious long-term complications for an injured team member.

- ALWAYS USE SAFETY SLINGS. When any component (pipe, hose and couplings) is suspended over workers, each item hanging from the boom should have its own safety sling. Slings must be inspected and rated for the entire load of the suspended system.

- ALWAYS INSERT THE SAFETY PIN. Due to the possibility of accidental opening, every snap coupling must be fitted with a safety pin at installation. Only safety pins designed for the job should be used with snap clamps. Pins should only be removed when it is confirmed that the system is not under pressure.

If you must use snap couplings, be mindful of the risks, be on the alert for any signs of wear and tear — and take all recommended safety precautions.