Optimizing Mix Design: Part 1

ACI CODE 323 AND ITS IMPACT ON CONCRETE PUMPING - Exploring Challenges and Adaptive Strategies

by Jon S. Belkowitz, PhD, PE; Mallory A. Westbrook; Daniel M. McCoy, PE

The introduction of ACI Code 323 on low-carbon concrete marks a pivotal shift in pushing sustainability within the concrete industry. Its primary objective is clear — reduce global warming potential (GWP) by revisiting the fundamentals of concrete mix design, material sourcing and production techniques. By incorporating provisions for environmental product declarations (EPDs), ACI Code 323 facilitates greater transparency and accountability for lifecycle environmental impacts. The code applies to sizable projects such as buildings over 50,000 square feet and pavements or other structures exceeding 7,500 cubic yards.

While fostering environmental sustainability, these regulations present substantial complexities for concrete pumping professionals. Changes in materials and mix designs to meet the low-carbon thresholds lead to ripple effects throughout the construction process, placing tangible new burdens on pumping operations.

This paper provides a surface analysis of ACI Code 323’s requirements, its impacts on pumping operations and actionable strategies to address emerging challenges. The effects of concrete mix design adjustments, including higher pump pressures, will be closely examined to help the industry adapt without compromising on safety, efficiency or compliance with the code.

HOW ACI CODE 323 AFFECTS CONCRETE MIX DESIGN AND PUMPING OPERATIONS

To comply with the low-carbon provisions, ACI Code 323 outlines adjustments to concrete formulations that necessitate a reduction in cementitious paste content, compensation via increased granular skeleton (rock and sand proportions), and the extensive use of chemical admixtures such as superplasticizers. While these modifications reduce GWP, they introduce operational hurdles for concrete pumping professionals.

Key Challenges Faced

1. Higher pump pressures

- Reducing paste content diminishes the natural lubrication within the concrete mix, increasing internal friction along pumping lines. Coupled with increased volumes of aggregate, this necessitates significantly greater pumping pressure to maintain standard flow rates.

- A major concern here is the increase in pump blowouts, raising safety risks, downtime and liability issues.

2. Accelerated equipment wear and higher costs

- Increased pump pressures lead to accelerated wear on pumping equipment — from pipes to hoses and pump cylinders. This results in higher maintenance and repair costs, while also shortening equipment lifespan.

- Greater energy demands for pumping operations contribute to increased fuel consumption, adding to operational costs and environmental impacts.

3. Reliance on chemical admixtures

- The need for admixtures like superplasticizers and viscosity-modifying agents (VMAs) has become critical to achieving workability in stiffened low-carbon mixes. However, improper calibration of these additives may lead to inconsistent field performance and placement challenges.

EXAMPLE OF A SUSTAINABLE MIX DESIGN

To better illustrate the above challenges, consider a concrete mix design and the low-paste version of the concrete mix designed to meet ACI Code 323’s GWP thresholds.

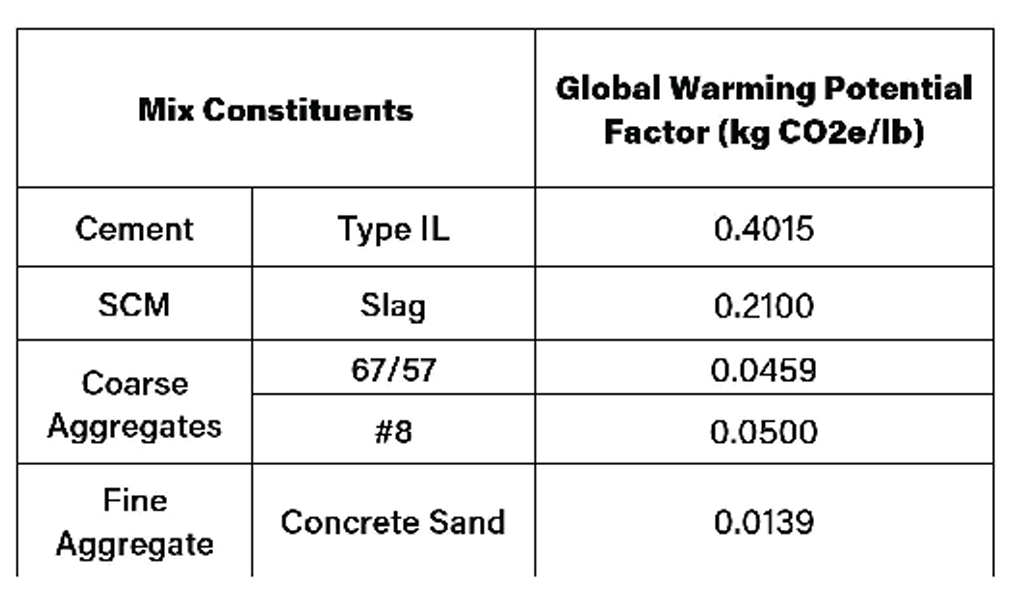

Table 1 is a list of the common materials available to civil engineers and concrete producers for the GWP evaluation — note that the only numbers used in the calculation are the cementitious and granular skeleton.

Table 1: CO2 Equivalent of Raw Materials Intended for Concrete Production

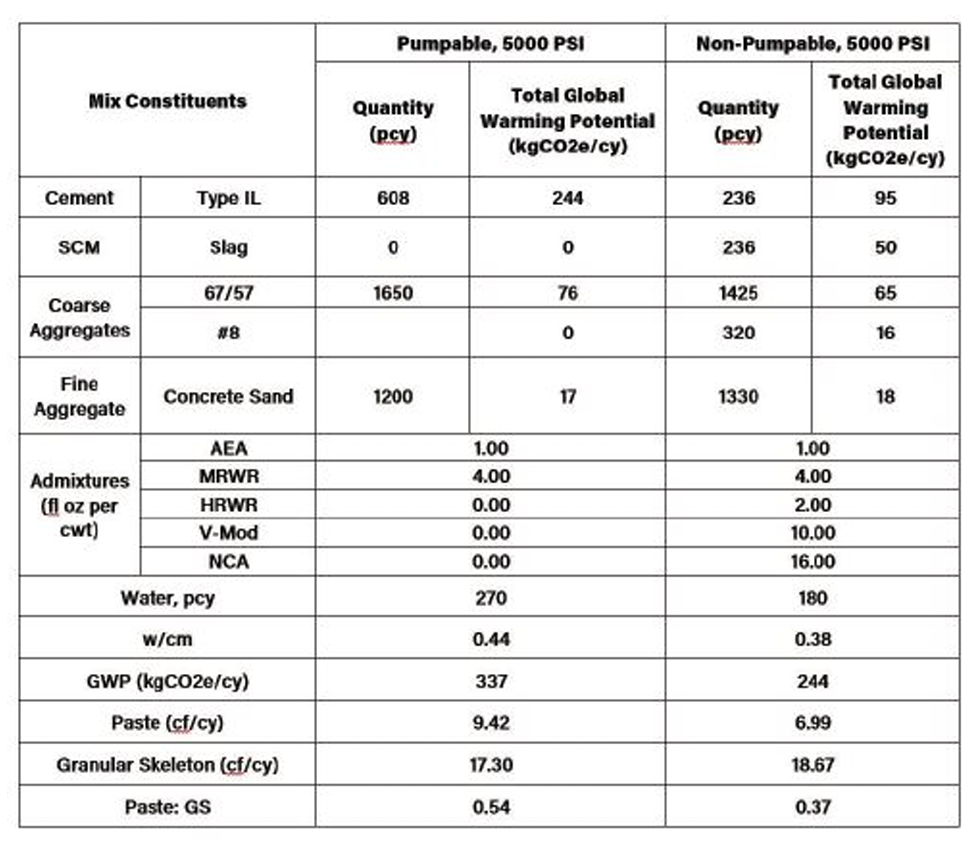

A concrete mix designed to be pumped and to develop a compressive strength of 5,000 psi at 28 days is compared to the same mix but with the required ACI Code 323 and GWP guidelines for low-carbon concrete. Notice from the mix design provided, the paste content is reduced by more than 25 percent, replaced by a high granular skeleton composition.

To compensate for the reduction in paste, superplasticizers and VMAs are incorporated to enhance flowability and the lubrication that would have been from the excess cementitious paste.

While the mix achieves the necessary properties for compliance, the reduced lubrication within the pump lines would lead to an increase in pump pressure. For pumping systems, this translates to additional fuel consumption, higher wear rates in pipes, and increased financial and safety concerns in the field.

Table 2: Concrete Mix Design with GWP Values

STRATEGIES FOR ADAPTING TO LOW CARBON CONCRETE CHALLENGES

Implementing adaptive measures is critical to maintaining efficient, safe and cost-effective operations under ACI Code 323 while supporting sustainability goals. Here are some strategies for concrete pumping professionals and stakeholders alike.

1. Collaborate and optimize mix designs

- Partner with concrete producers to test and refine the balance between reduced paste content and increased granular skeleton.

- Use modeling software to simulate pump flow and pressures with specific mix designs, optimizing parameters during the planning phase.

2. Focus on enhancing pump equipment performance

- Invest in high-pressure pumps and equipment specifically designed to handle the stress of low-paste mixes.

- Ensure rigorous preventive maintenance schedules to reduce wear-related failures.

3. Leverage advanced admixture technologies

- Work closely with suppliers of admixtures to understand the advanced capabilities of next-generation chemical additives.

- Target field optimization by calibrating admixture performance for specific project conditions.

4. Monitor and document performance

- Develop a comprehensive documentation protocol covering pump pressures, flow rates and mix adjustments across all projects.

- Tracking historical data will allow professionals to anticipate challenges and refine processes over time.

5. Engage with regulatory committees

- Support industry-wide collaboration to identify practical adjustments to ACI Code 323 standards where operational impacts are most acute.

- Advocacy for testing incentives and the development of alternative compliance measures could reduce the immediate strains on pumping operations.

WHY THE INDUSTRY SHOULD ACT NOW

The industry-wide implications of increased pump pressures — from economic to environmental — necessitate immediate attention and collaboration. Without proactive adaptation, companies risk facing escalating costs, equipment failures and safety concerns. ACI Code 323 is just the beginning of a broader regulatory landscape that prioritizes sustainability. Concrete pumping professionals can serve as valuable collaborators in shaping future codes, ensuring both environmental and operational excellence.

CONCLUSION

ACI Code 323 on low-carbon concrete forces the concrete industry into a new era of sustainability, but not without presenting significant operational challenges for pumping professionals. Changes to concrete mix designs, particularly reductions in paste content and increased pump pressures, demand innovative responses. Proactively addressing these challenges — through strategic alliances, optimized equipment use and engaging with regulatory bodies — will not only prepare your business to comply with ACI Code 323, but also position it as a leader in sustainable construction practices.

For further insights, references and collaboration opportunities, reach out to the industry experts shaping this conversation. Together, we can innovate towards a future that balances low-carbon sustainability with operational efficiency.